Iron oxide is bringing winds of change to the manufacturing sector

Iron oxides are pretty common naturally occurring compounds. Also, they can be made synthetically in a laboratory. Iron oxides are composed of Fe, O, and (or) OH. The most important oxides of iron are magnetite and hematite.

Applications

Iron oxides have a lot of industrial applications. For instance –

- As per the marketing head of one of the leading iron oxide red manufacturers in India, the entire steel industry of India and the rest of the world rely on iron oxide as the primary source of iron. Steel is an alloy of several elements mixed with iron and carbon. However, the composition of steel is more than 95% iron as the base metal.

- Iron oxide pigment manufacturers in India and the rest of the world supply high quality iron oxide to paint and pigment manufacturing plants. Iron oxide derived from haematite is one of the primary raw materials for making striking red pigments. Iron oxide-based red pigment is then used to make specialized coatings and paints.

- Iron oxide is also used by ink manufacturers as well as cosmetic product manufacturers.

Iron oxide is also used to produce iron oxide nanoparticles

Black iron oxide manufacturers in India are also witnessing a sudden demand from overseas for large consignments of iron oxide. The demands are coming from brands that are associated with the production of iron oxide (IO) nanoparticles.

What are iron oxide nanoparticles?

Iron oxide nanoparticles consist mainly of maghemite and (or) magnetite with very small diameters (typically in the range of 1 – 100 nanometers!).

What are the applications of iron oxide nanoparticles?

The primary applications of iron oxide nanoparticles are in –

- Magnetic data storage

- Biosensing

- Drug delivery, etc.

Other reasons behind the popularity of IO nanoparticles

Iron oxide nanoparticles also have shown in several controlled studies that they have superparamagnetic properties. Furthermore, iron oxide nanoparticles also have the right properties (like non-toxicity and biocompatibility) in them that allow them to have significant biomedical applications.

In recent years, several large-scale improvements have been made in the processes of making water-soluble and organic iron oxide nanoparticles. These developments opened up new avenues for IO nanoparticles such as:

- Iron oxide contrast agents that can be used for MRI (Magnetic Resonance Imaging)

- Iron oxide nanoparticles act as excellent gene carriers for patients who need gene therapy

- IO nanoparticles can perform as therapeutic agents in cancer treatments that are hyperthermia based

- IO nanoparticles can also perform as magnetic sensing probes for IVD (in-vitro diagnostics), etc.

Conclusion

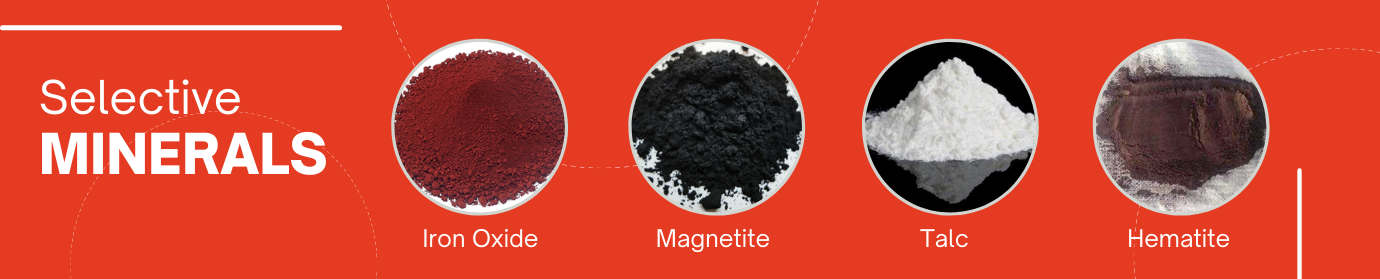

The future of iron oxide is bright. Every day new ways are being sought out where iron oxide can be used as a raw material to produce new products. To learn more about the applications of iron oxide, please contact Selective Minerals and Color Industries Pvt. Ltd. – an ISO 9001 – 2015 certified manufacturer and exporter of iron oxides, processed minerals, concrete and cement colours, talc powder, magnetite powder, hematite powder. The company has been in business since 1991. Contact details are +91-022-26499343 / +91-99209 46444 and sales@selectiveminerals.com / info@selectiveminerals.com.